Field trials, Surveys & Statistics

The S3AM technology, once launched, represents the culmination of rigorous field trials and surveys to ensure it is as efficient and accurate as possible in the field. Our research and data will be compiled over several years, reflecting different kinds of environments, conditions, and evaluation methods that are designed to make S3AM as practical, functional, and affordable for oyster cultivators as possible.

Explore the S3AM Research

Year One: Data Collection

To ensure wide-range applicability, the S3AM team will collect and analyze water quality data from U.S. estuaries and bays from sources including buoys and NOAA’s System Wide Monitoring Program for 12 U.S. coastal states.

Aside from water quality, the team will work with growers from three regions (East, Gulf, and West) to obtain complex bottom images using identical cameras and sonar sensors as those to be used in S3AM . This additional imaging will help the S3AM software distinguish live oysters from underwater grasses, small invertebrates, mud, sand, and cultch.

Year Two: Laboratory Tests and Evaluations

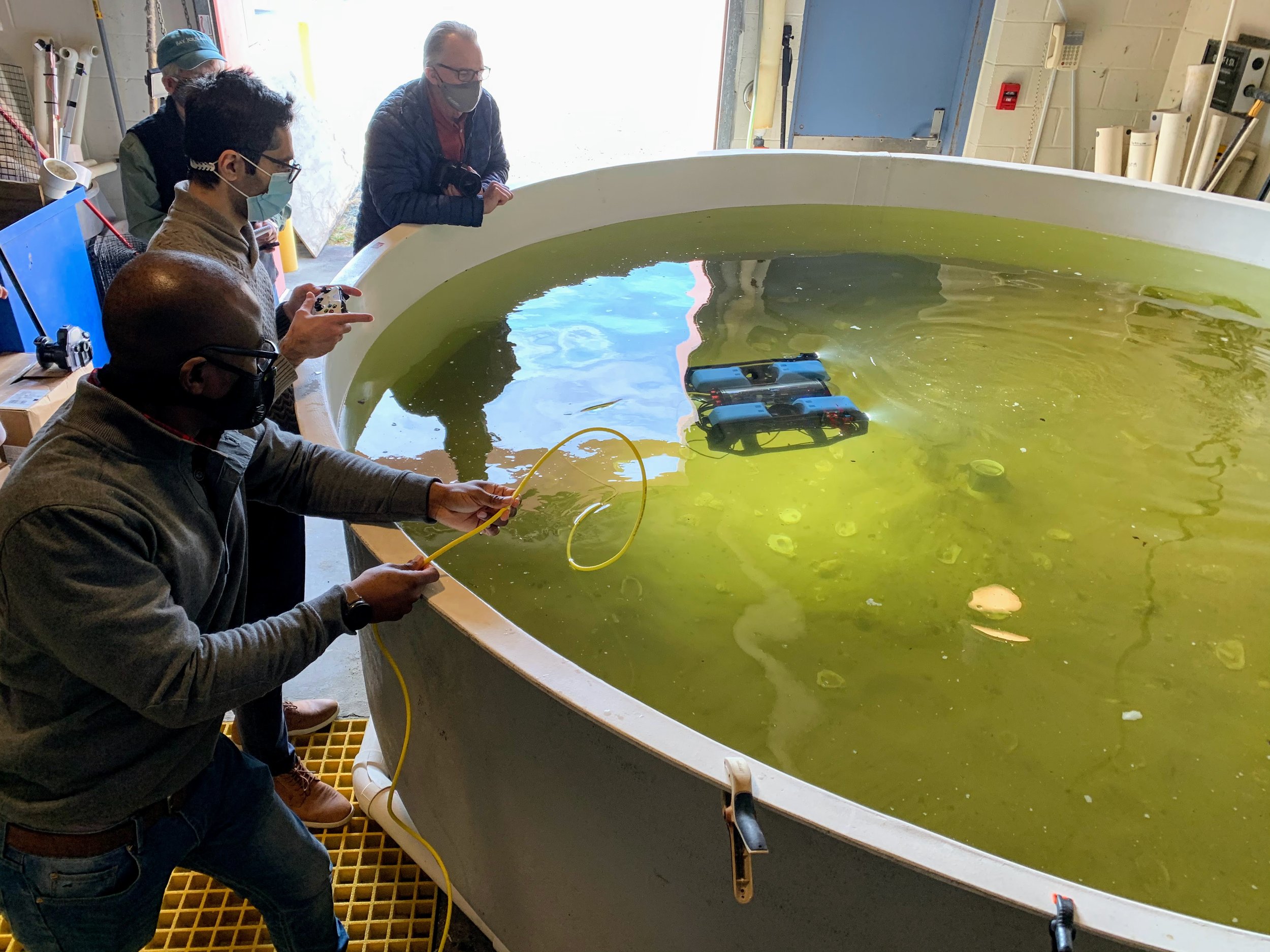

The S3AM team will use the images and information collected in year one to recreate a range of environmental conditions. These will be used to test the S3AM monitoring at UMCES Shellfish Aquaculture Innovation Laboratory, located in the Chesapeake Bay. At SAIL, S3AM will be repeatedly tested for use among various bottom sediment types, clear and murky conditions, and on oysters of various sizes. The feedback from this testing will be used to improve the S3AM technology prior to field trials.

Year Three and Four: Field Testing

At the 2.25 acre licensed shellfish lease at Horn Point Labs, field tests will be conducted in years 3 and 4 to evaluate shellfish gear and management practices.

S3AM will be used to evaluate different farm bottom types from soft mud and sand to firm rock or shell base, and will count oyster densities in nearby Sandy Hill Oyster Sanctuary using side-scan sonar and coring sediment samples. This will allow the team to assess S3AM measurements in field conditions, and to evaluate the performance of S3AM technology and operation before trials on an active lease.

S3AM will also survey active/ working bottom leases on the East, Gulf, and West coasts, in different region-specific conditions—including the macro-tidal environment of the Pacific Northwest. From a surface vessel, the team will pilot S3AM at each test site to dive on oyster beds and scan them. Over the course of a single season, multiple scans of the S3AM e beds will allow the team to track growth, mortality, and survival rates of shellfish. These successive scans will also track varying growth rates in a single farm, creating a shellfish size and location map of productivity for smart dredge harvesting to save time and labor costs.

Using data and modeling to ensure the financial feasibility of S3AM for industry use

Working with stakeholders in the shellfish industry across different regions and farming practices, the S3AM team will develop models for annual expenses and revenues to ensure the economic viability of the technology. Different factors will be assessed for maximum practical use, including:

production scale for each region

long-term real estate costs, including buildings for processing shellfish, hatcheries, shucking plants, and other shoreline facilities

equipment, including boats, dredges, winches, remote setting tanks

net returns, break-even costs, and break-even yields, and how they contribute to the overall production cost

This information will all be used to estimate a feasible break-even price point to make S3AM an affordable and profitable tool for farmers. The possibility of providing S3AM as a service through a specialized business, rather than requiring individual farm ownership, will also be explored—much like “custom farming” offered to land-based agriculture.